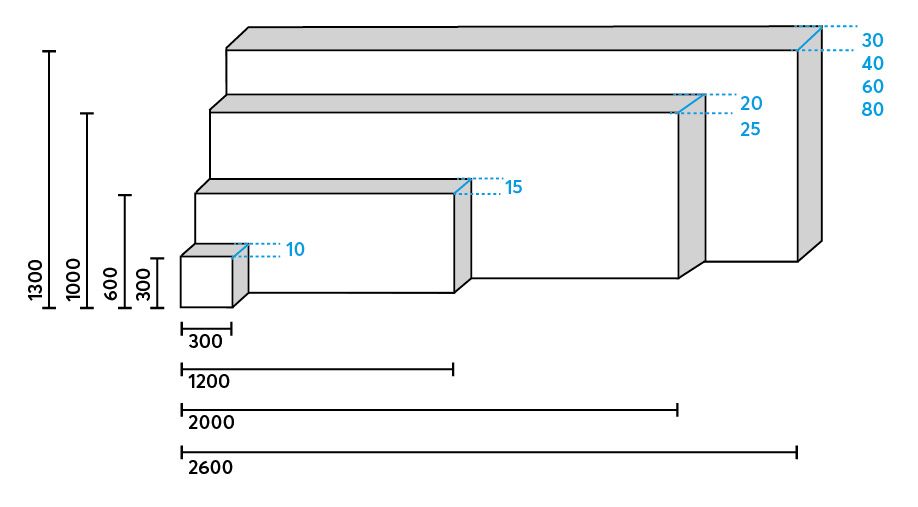

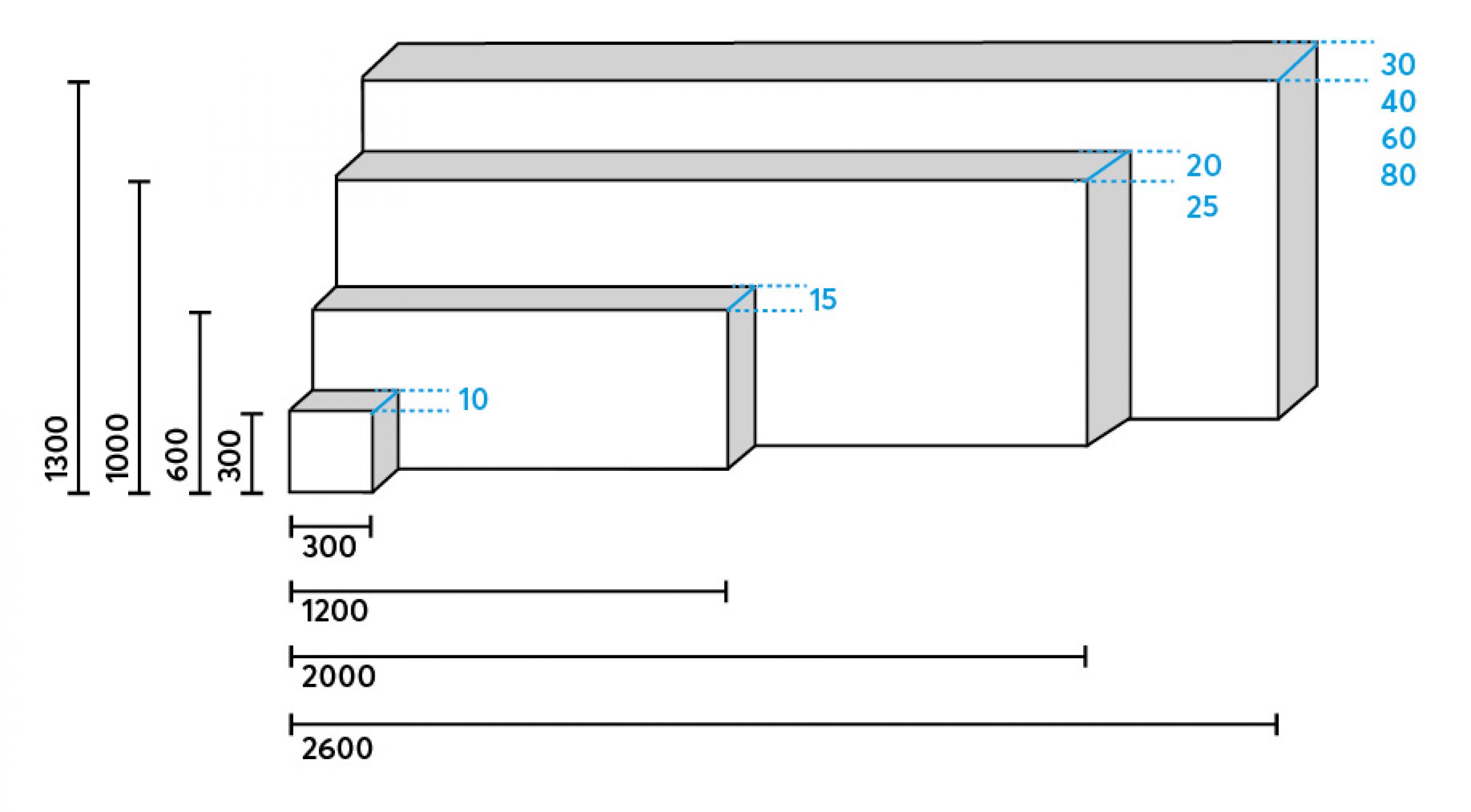

Format and Size

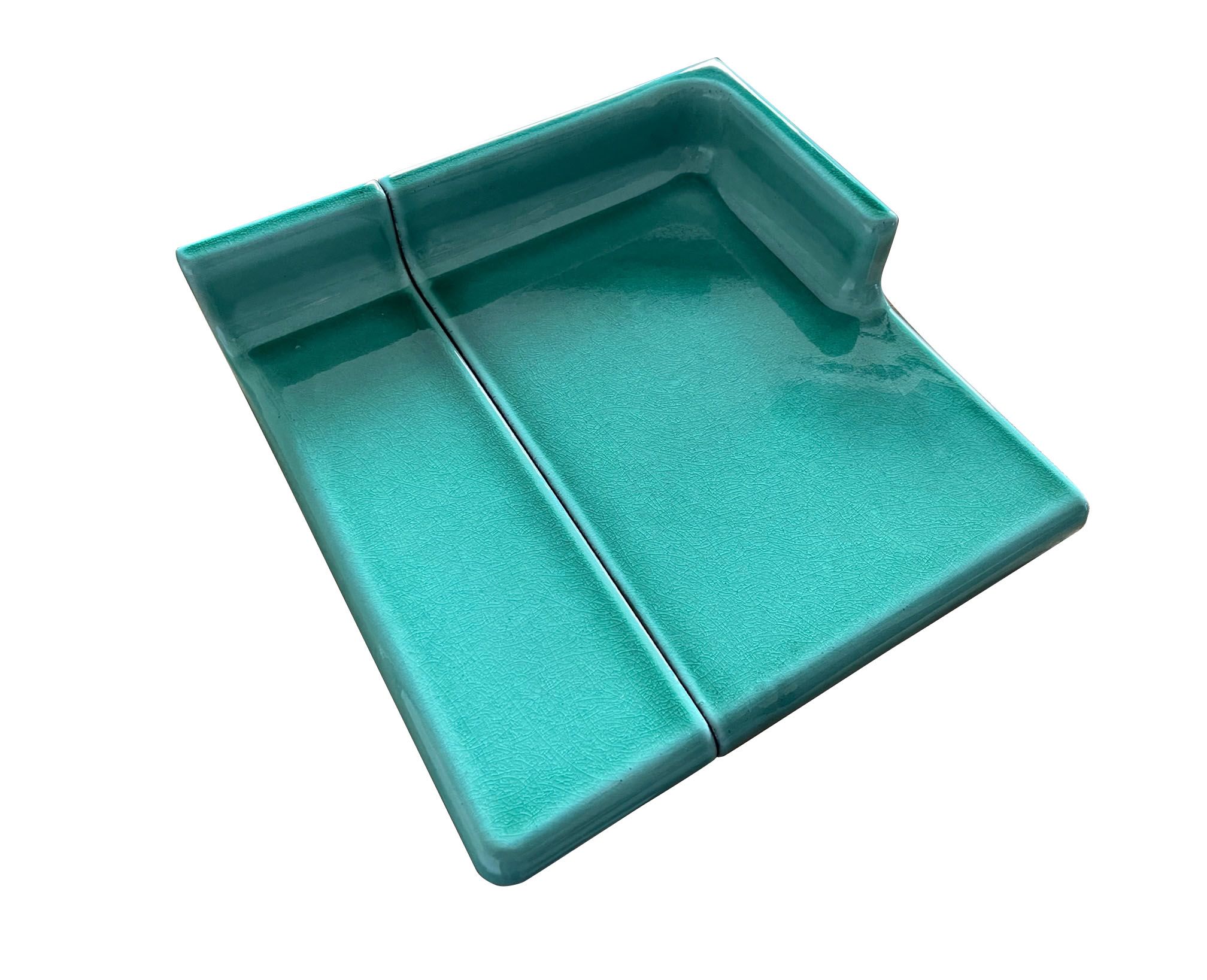

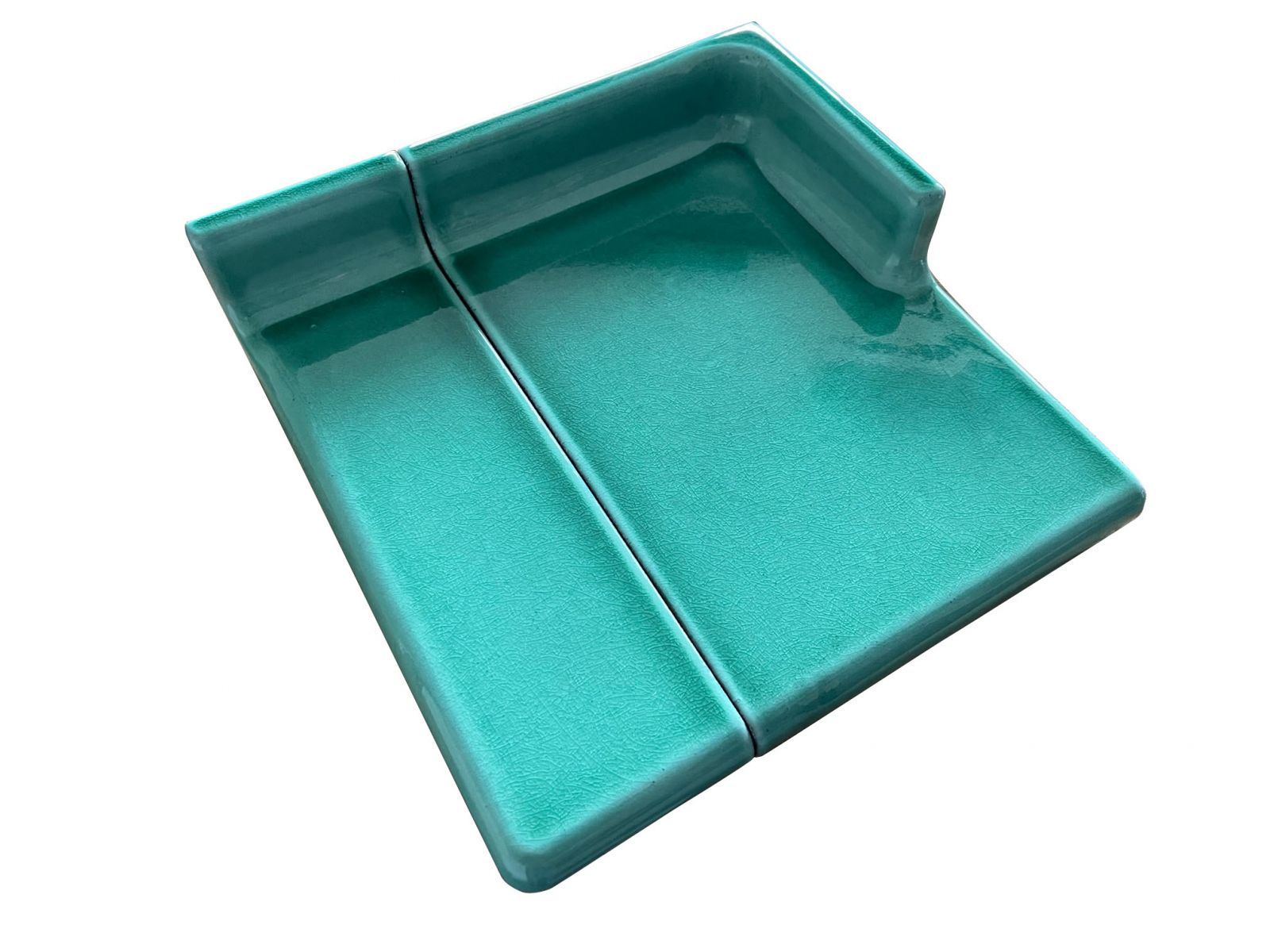

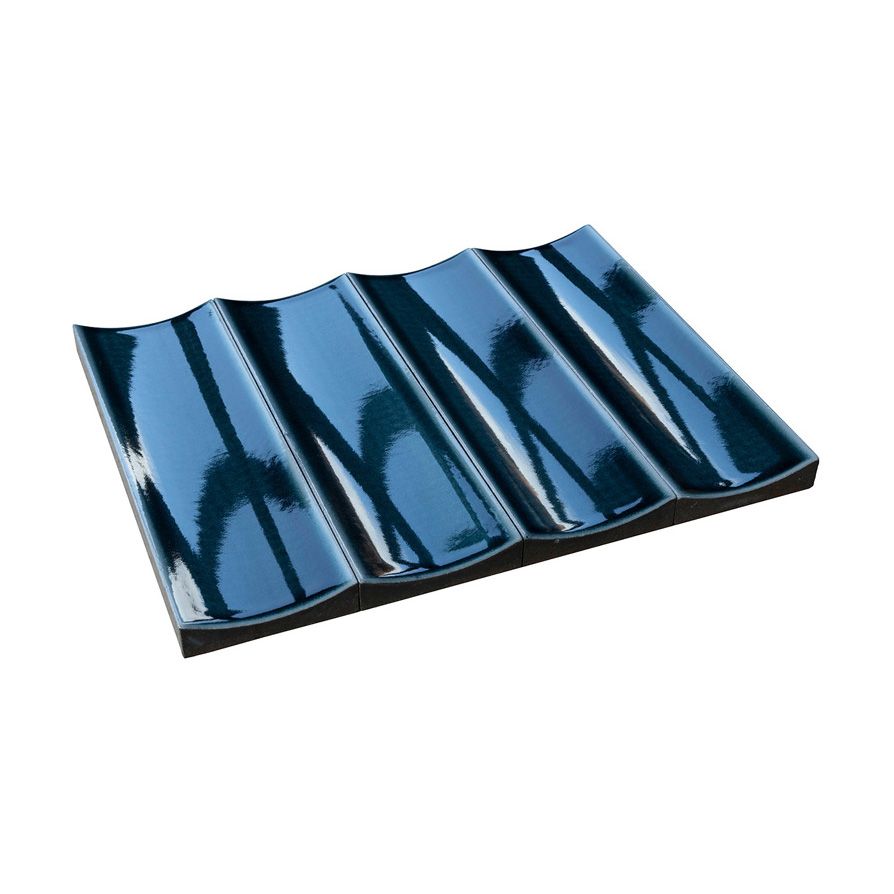

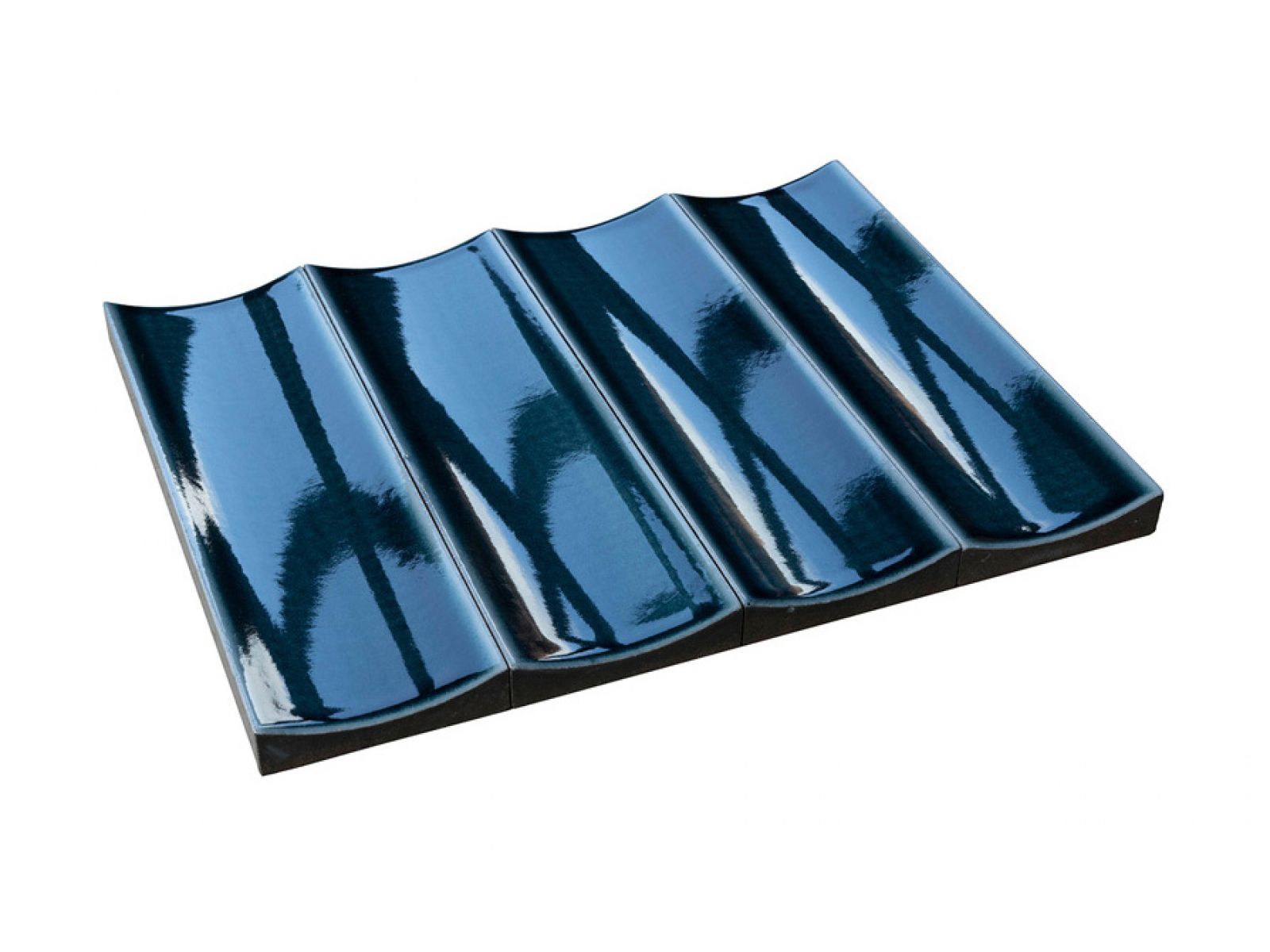

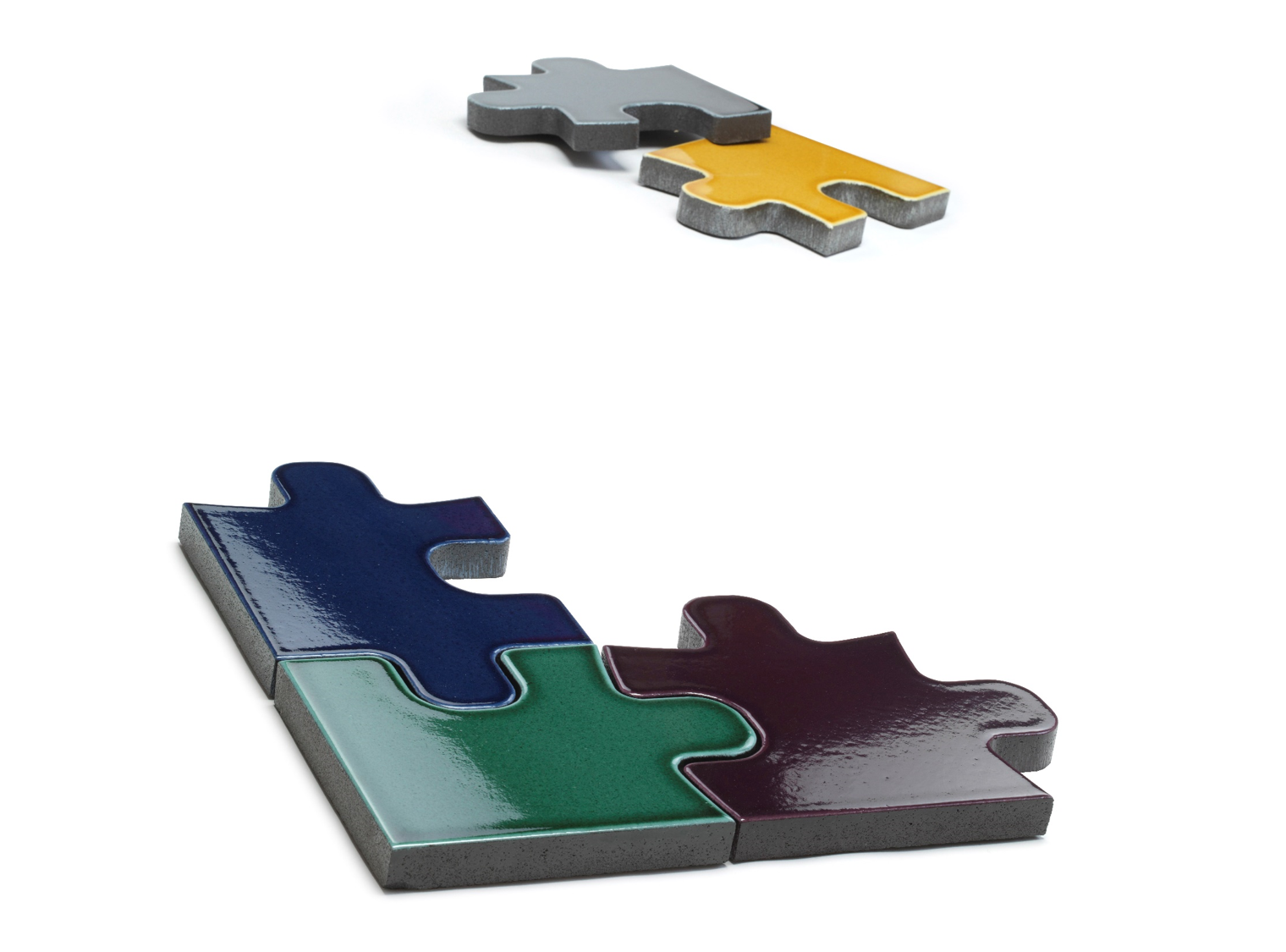

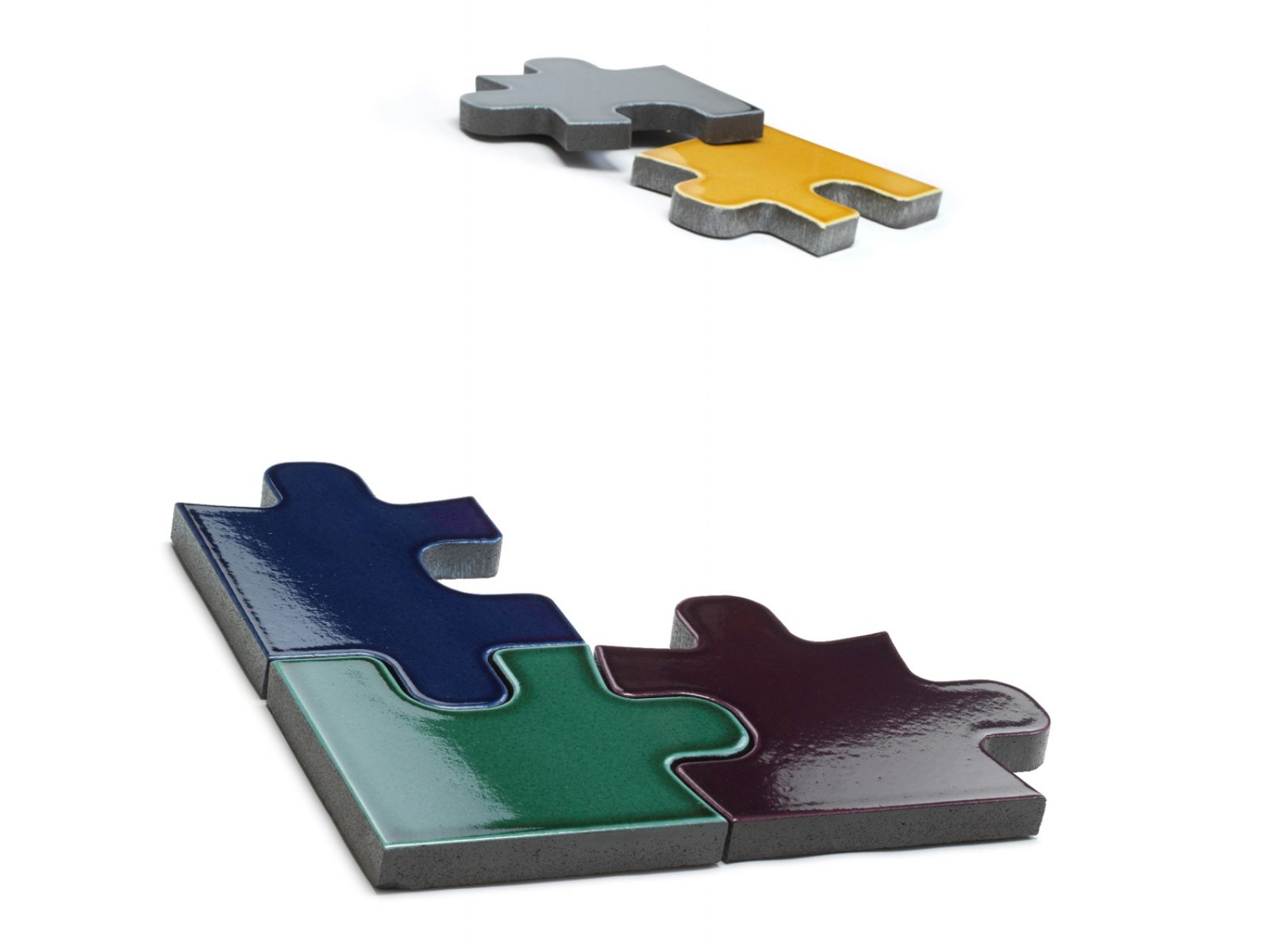

Pyrolave is shaped and finished to size and thickness specifications using CNC technology. This means highly creative designs and fluid shapes can be achieved.

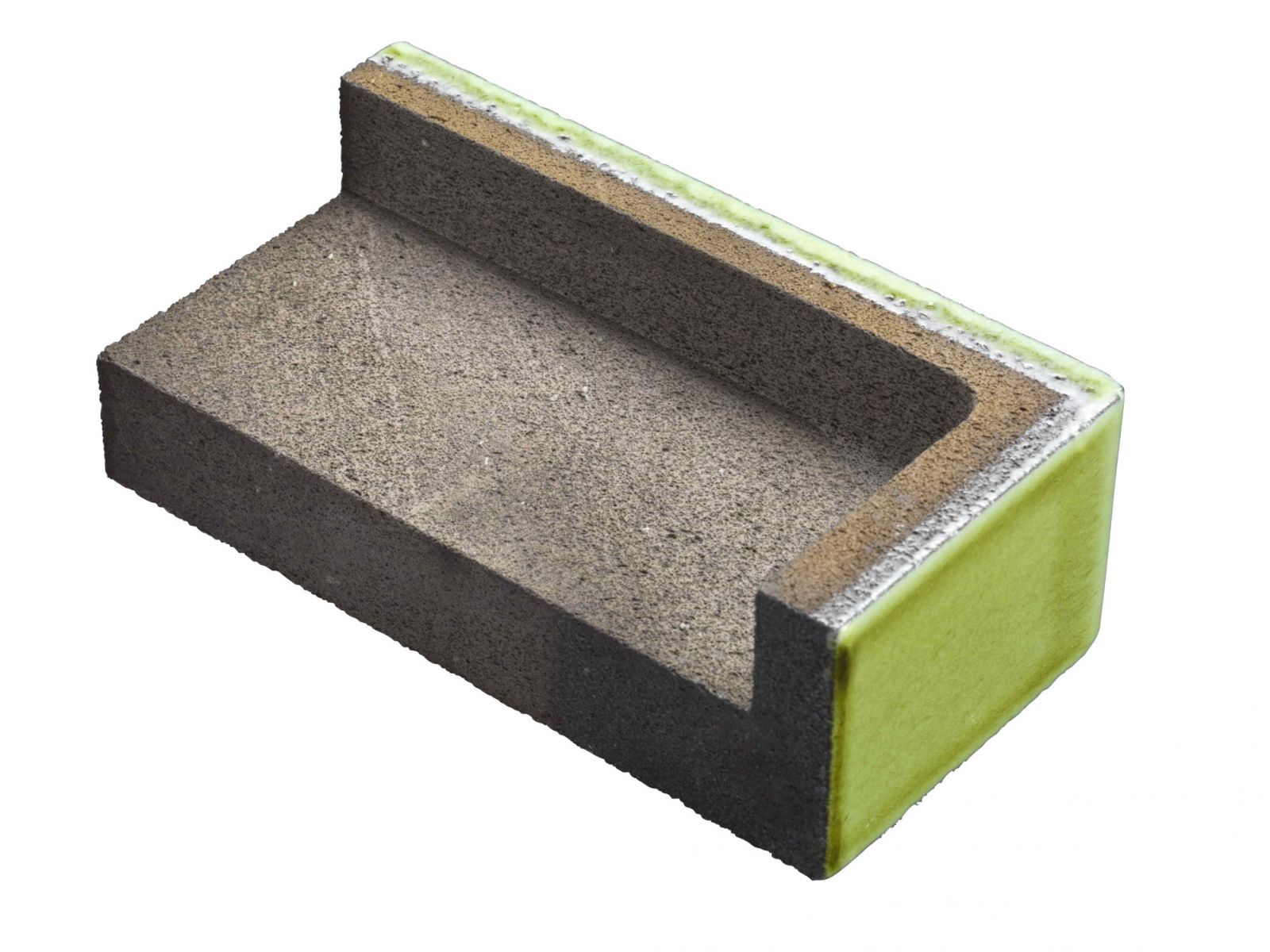

The stones strength and durability allows for the creation of formats honed from monolithic blocks of solid stone to create signature pieces, such as vanity and sink basins.

When designing your project, keep in mind the size to weight ratio of this uniquely dense material. Details below.

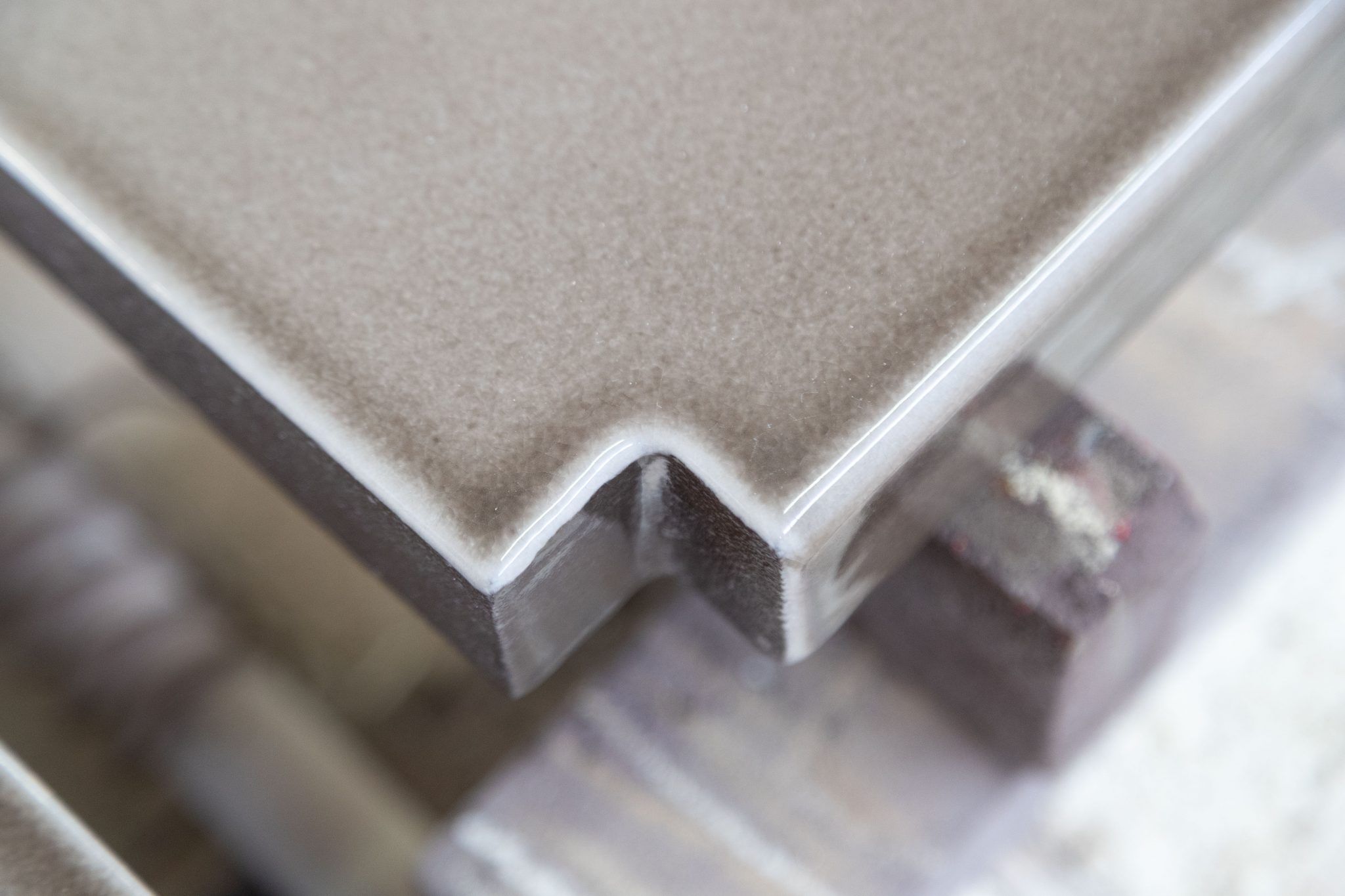

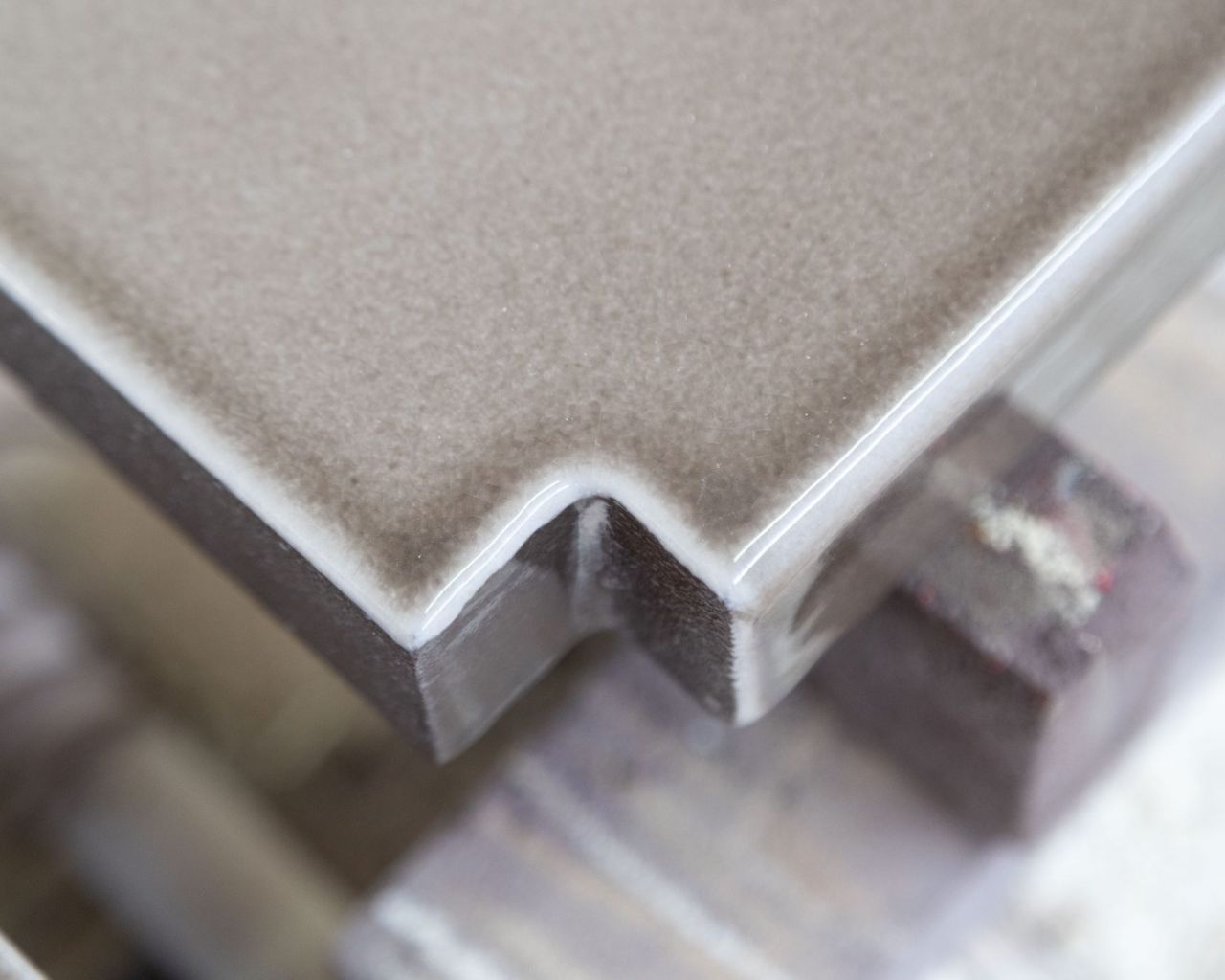

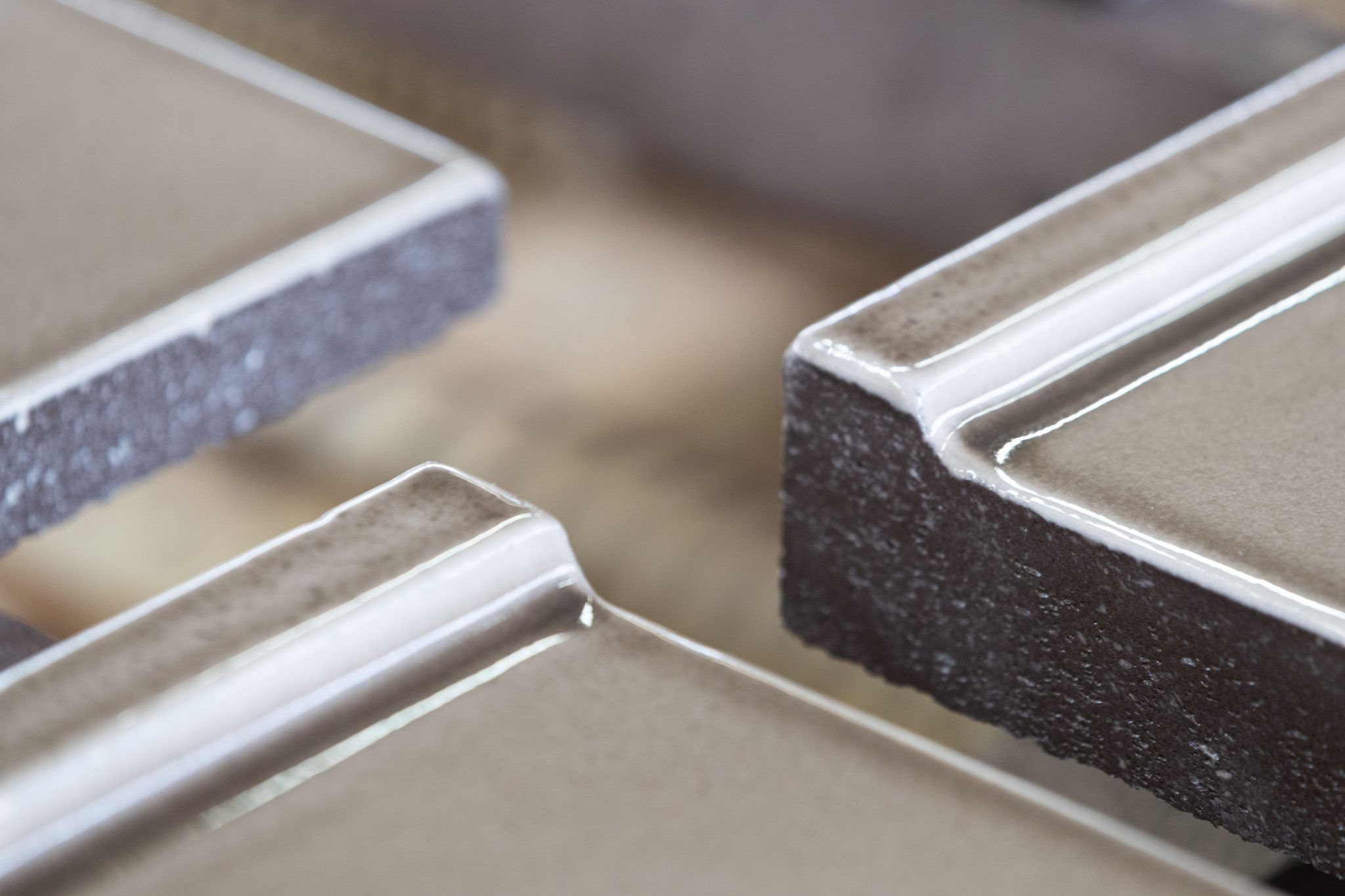

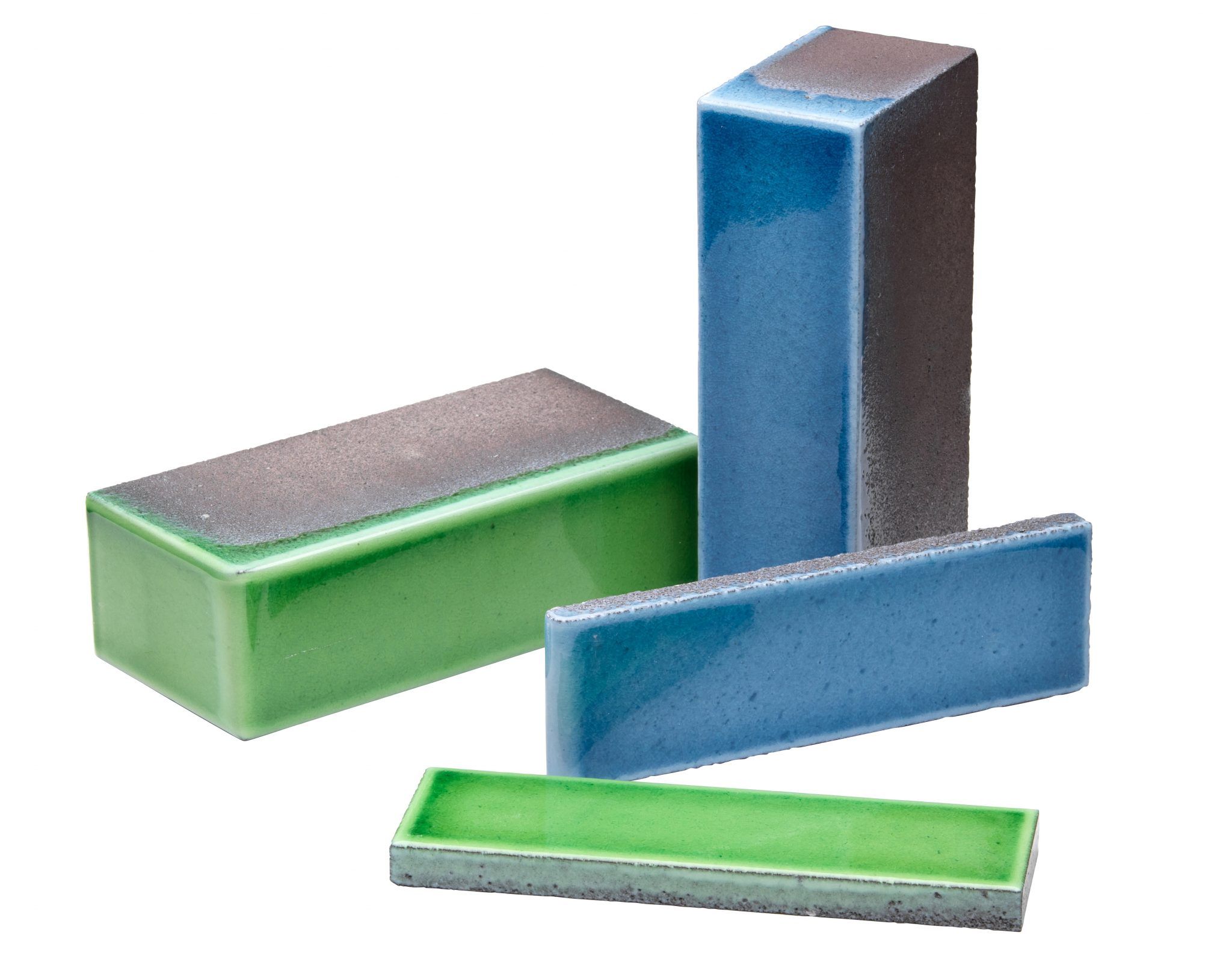

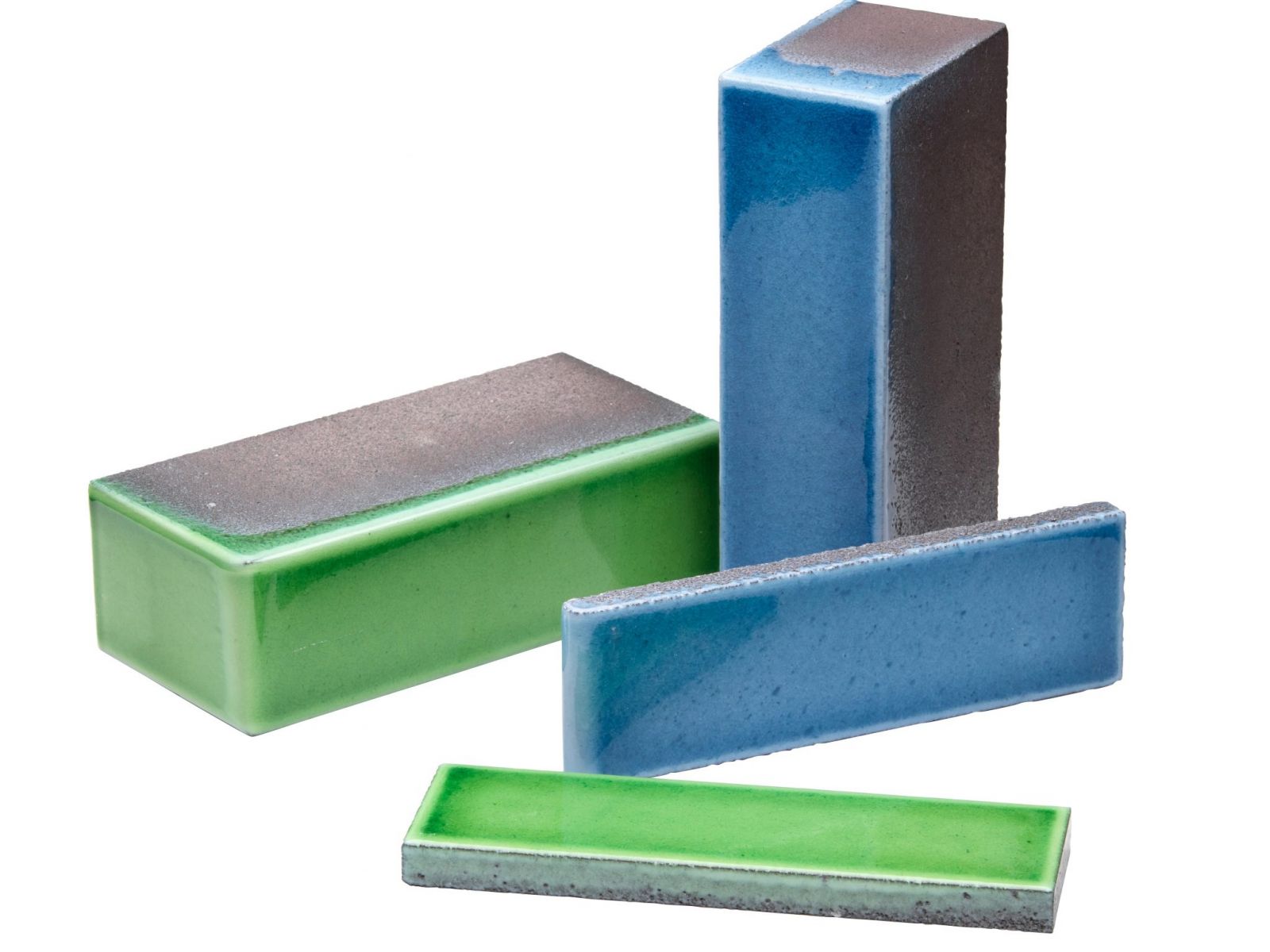

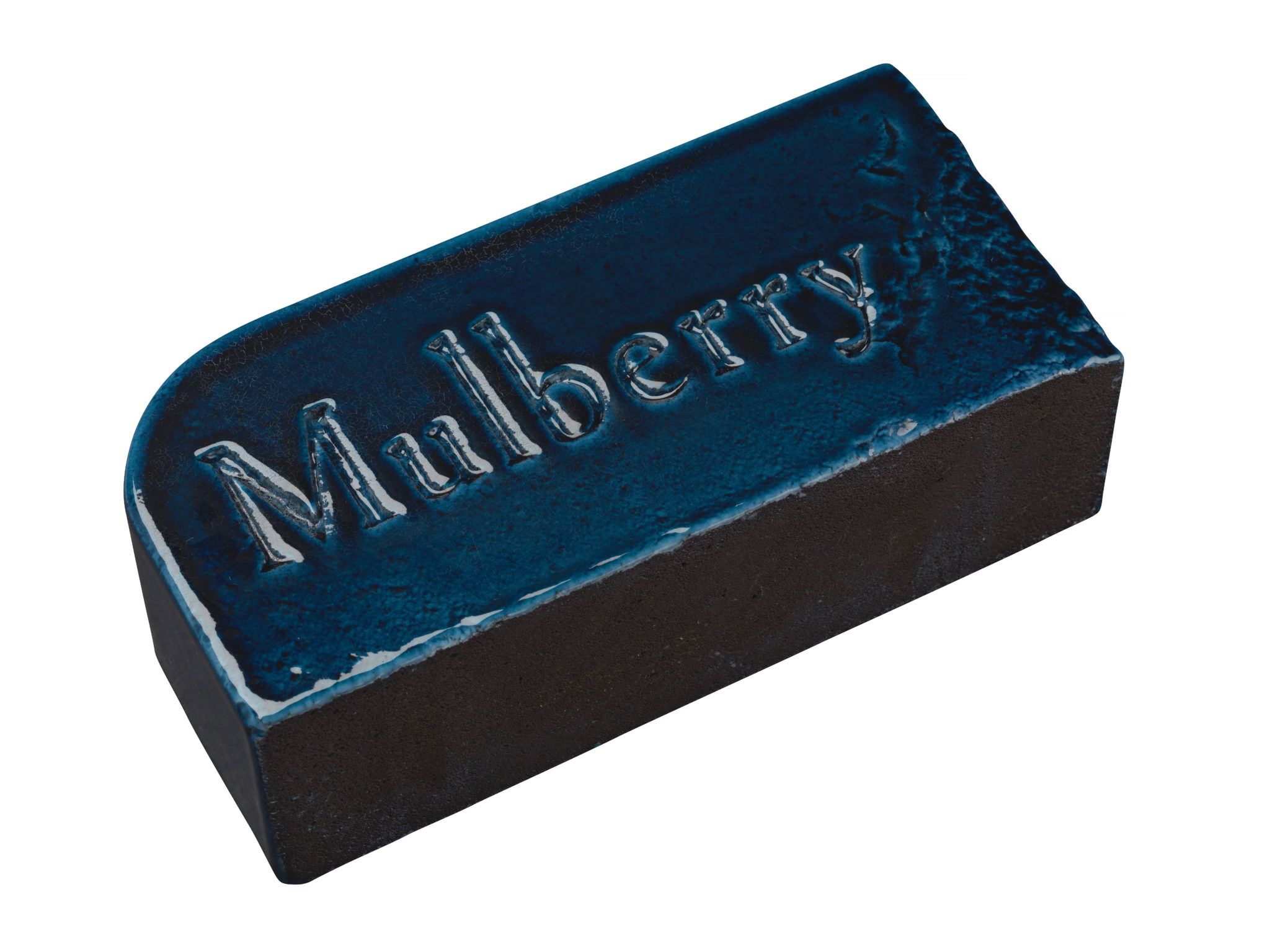

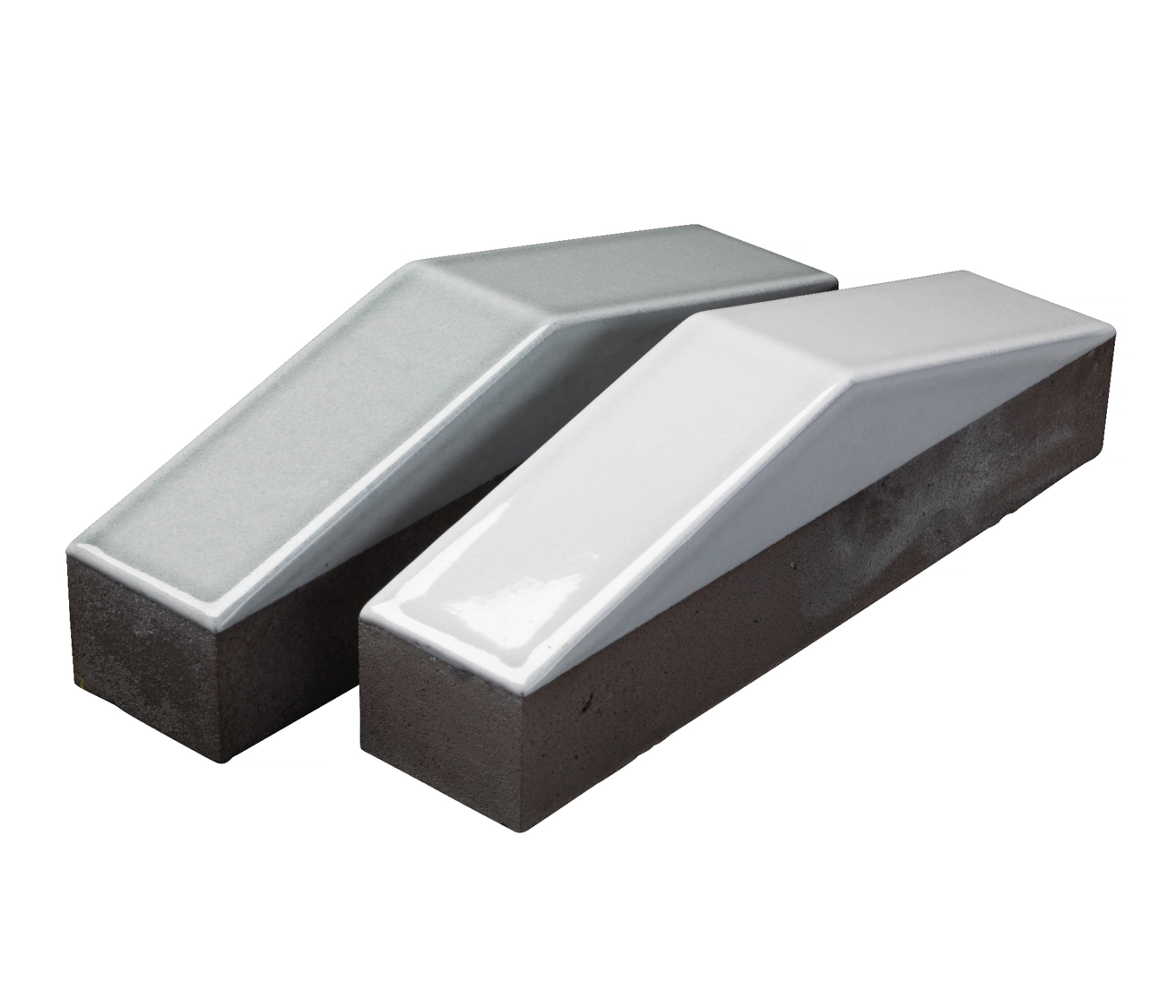

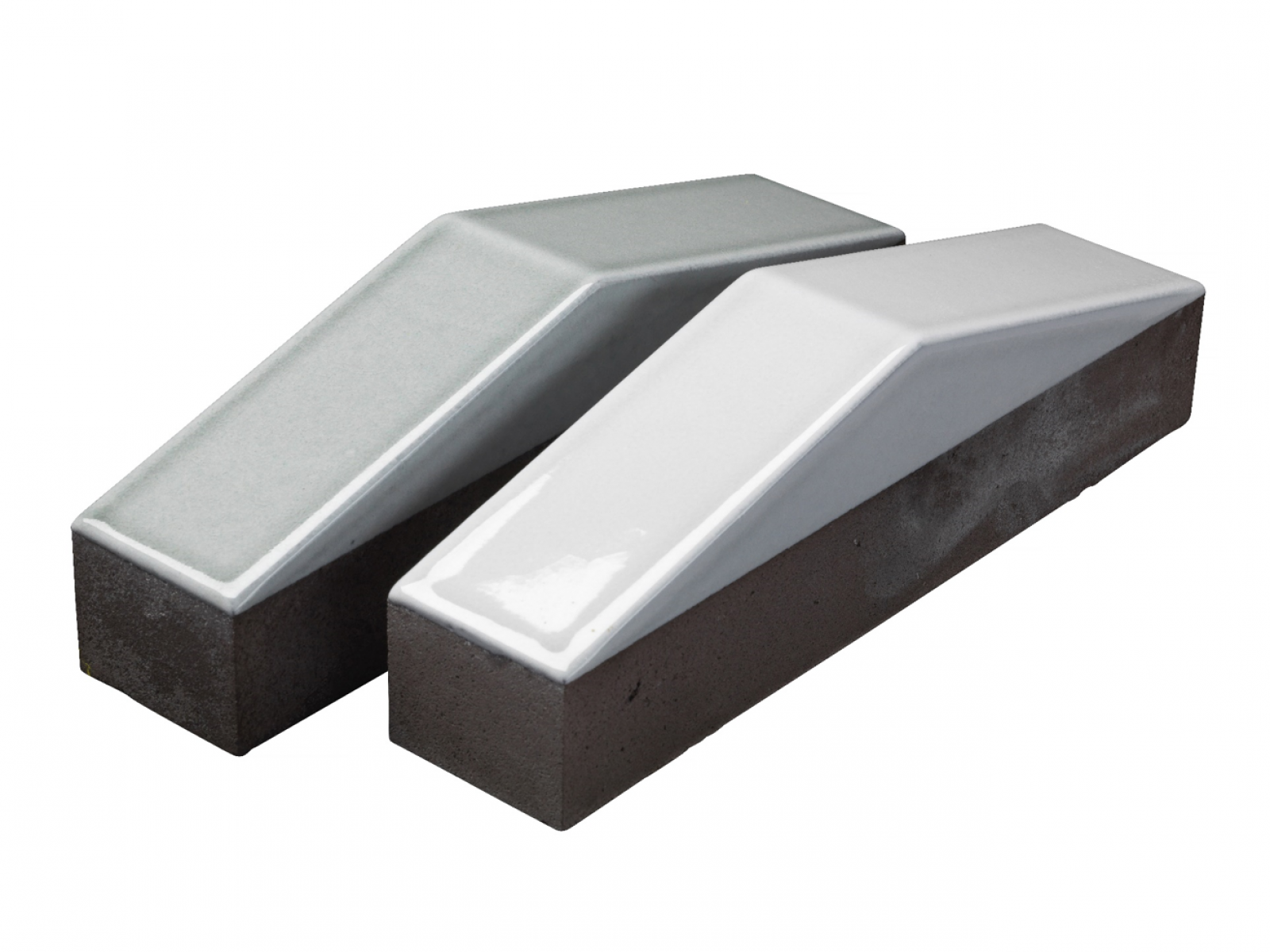

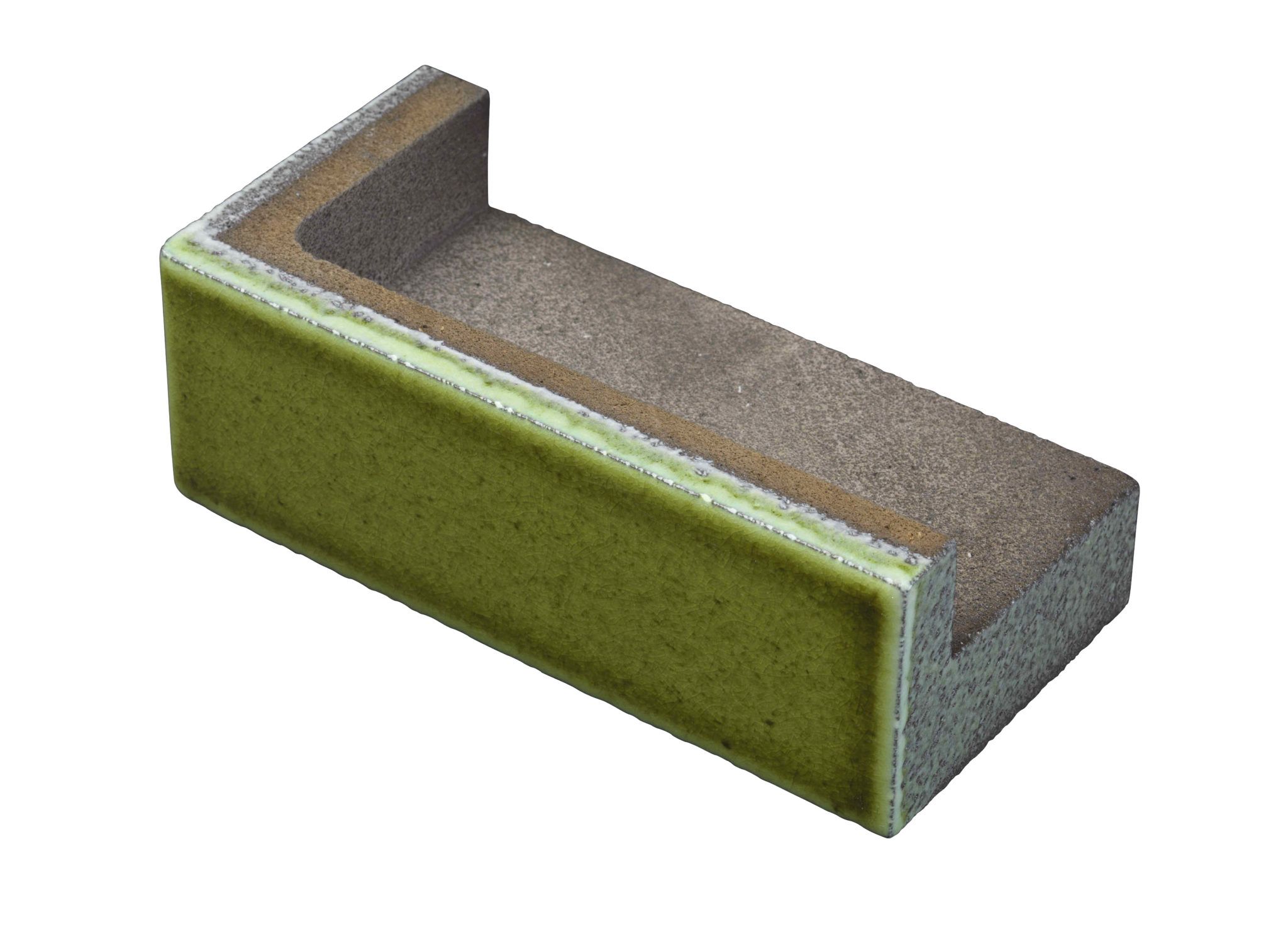

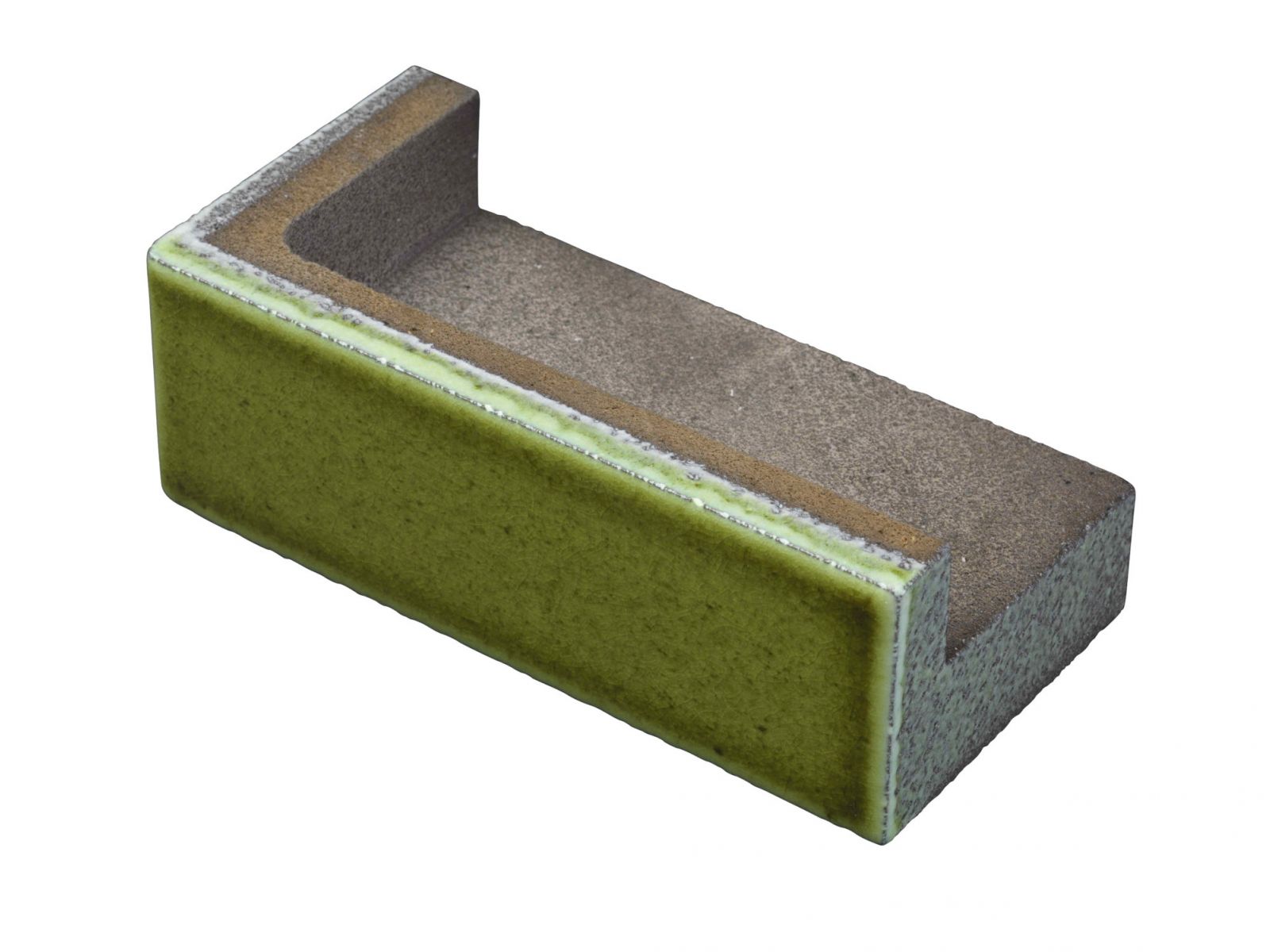

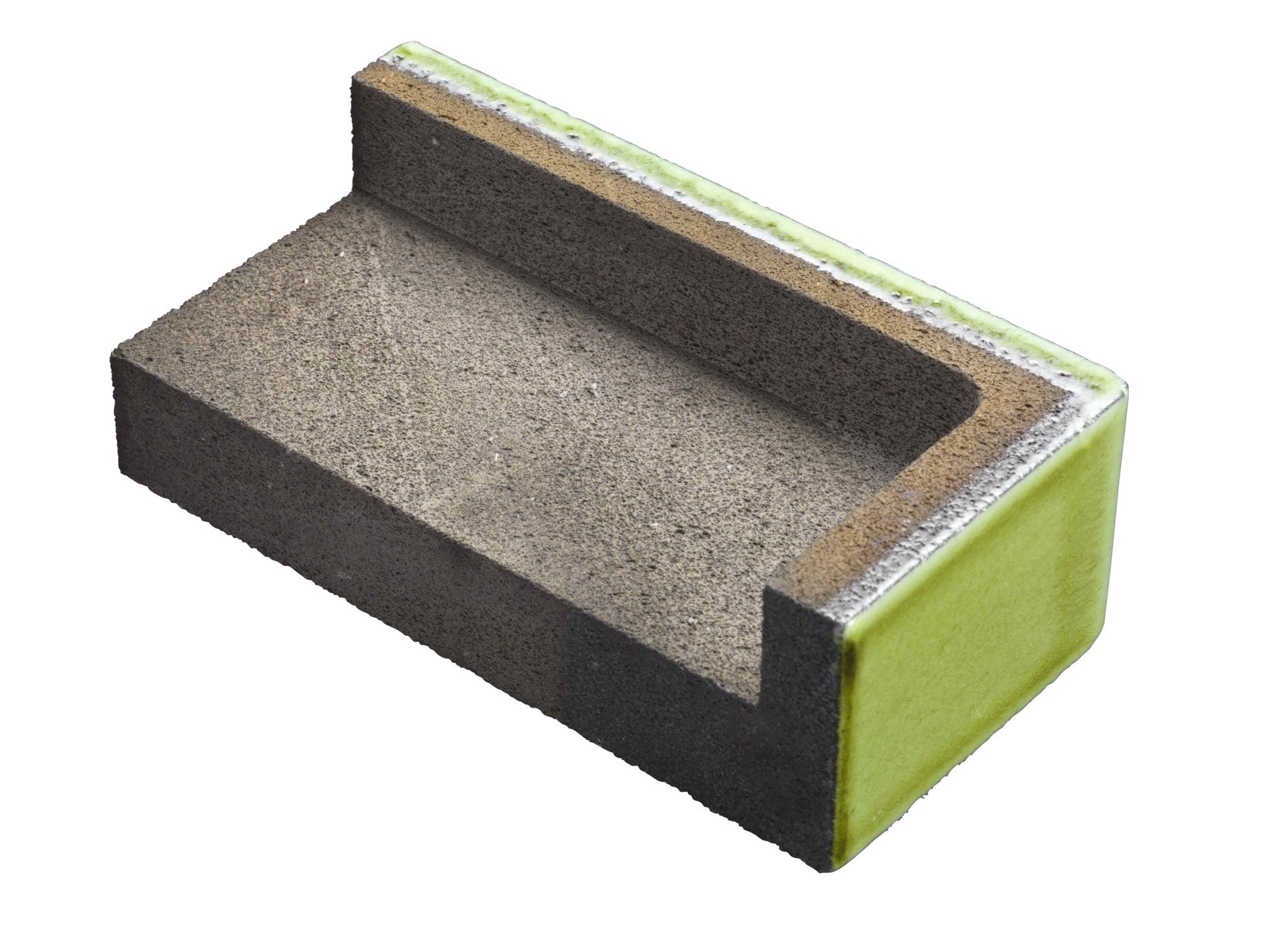

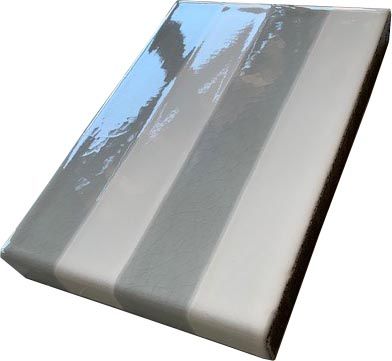

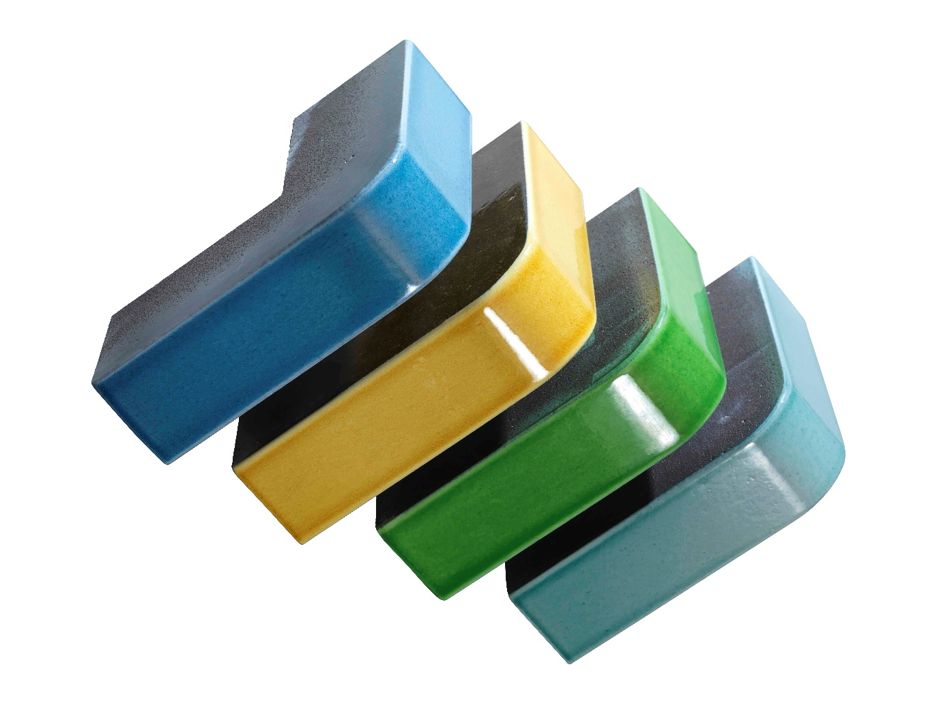

Edging

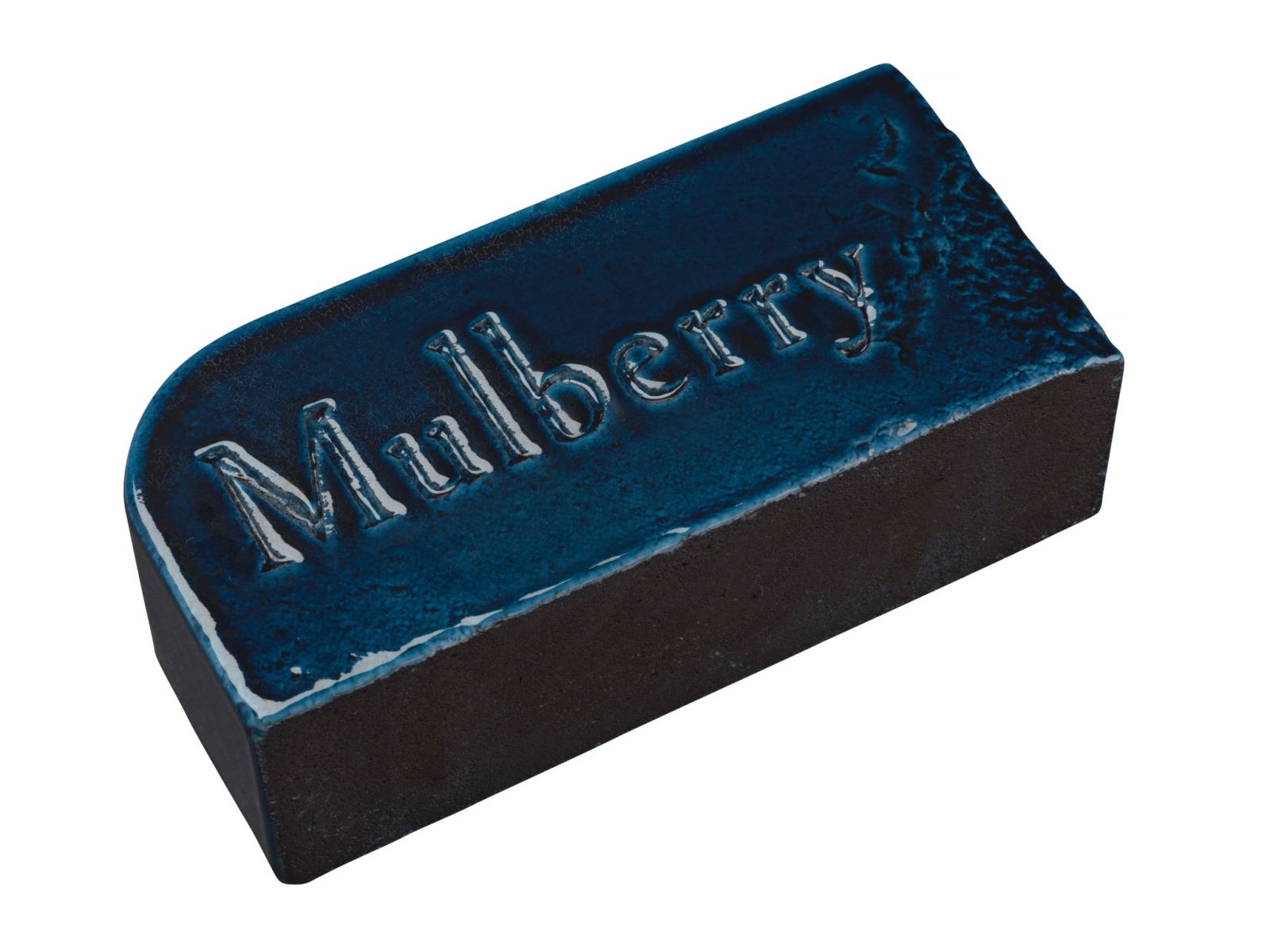

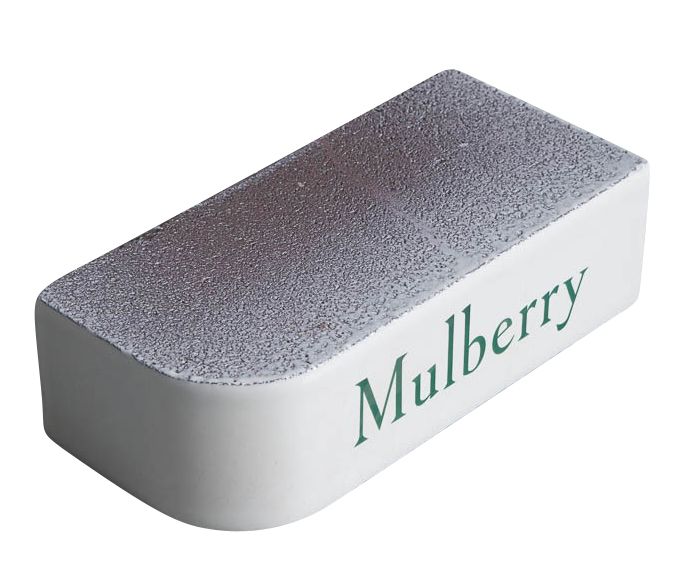

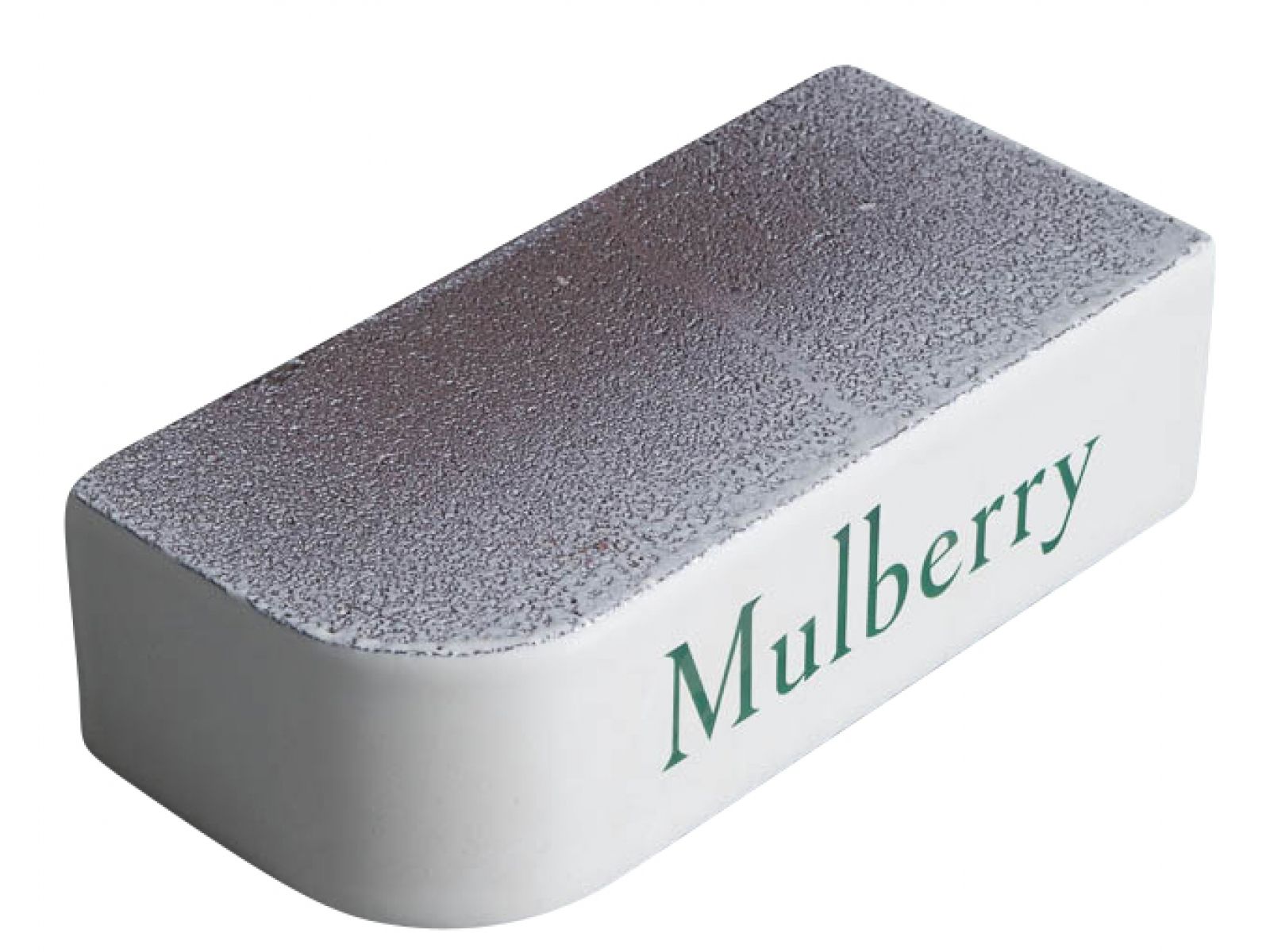

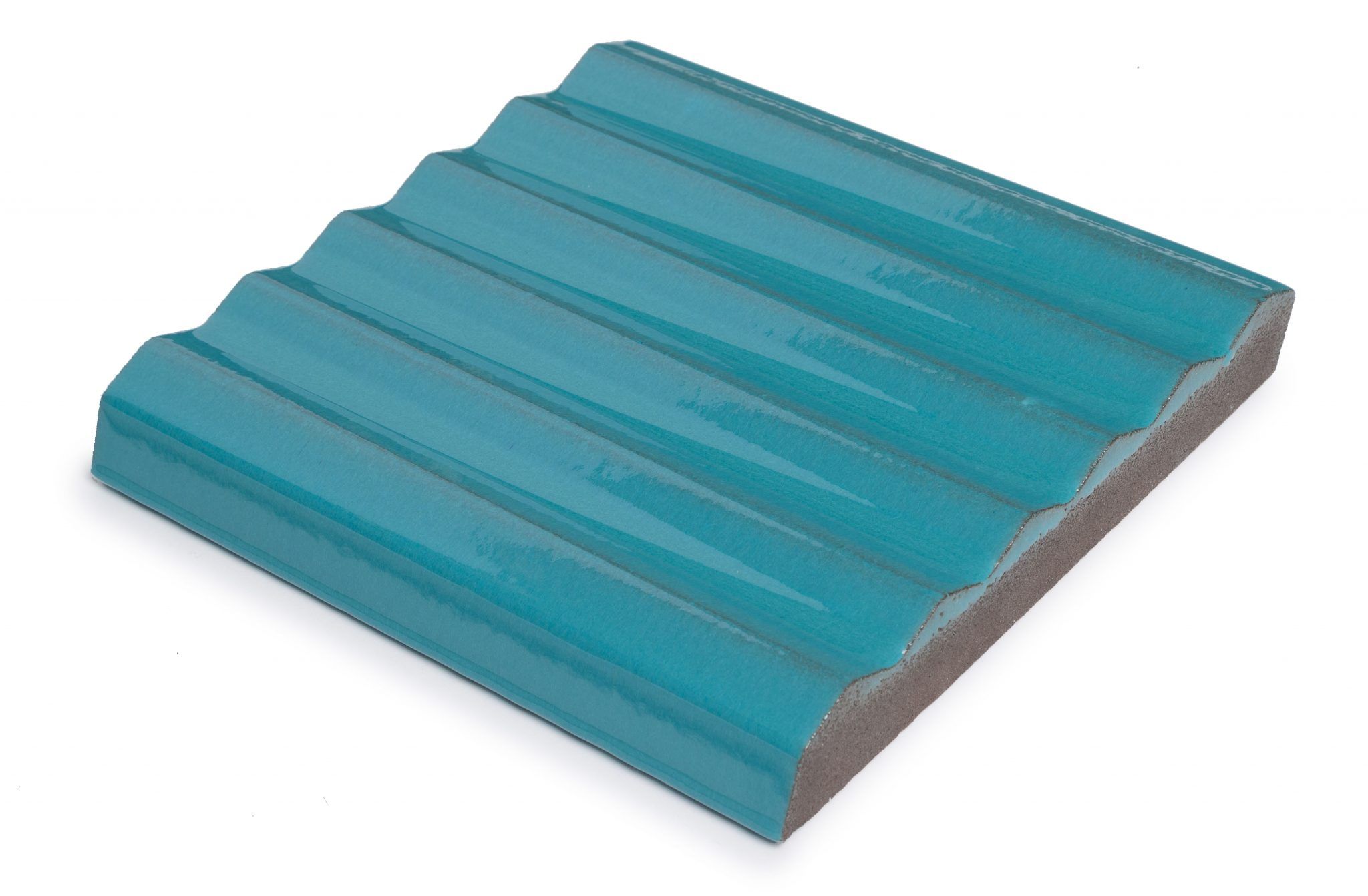

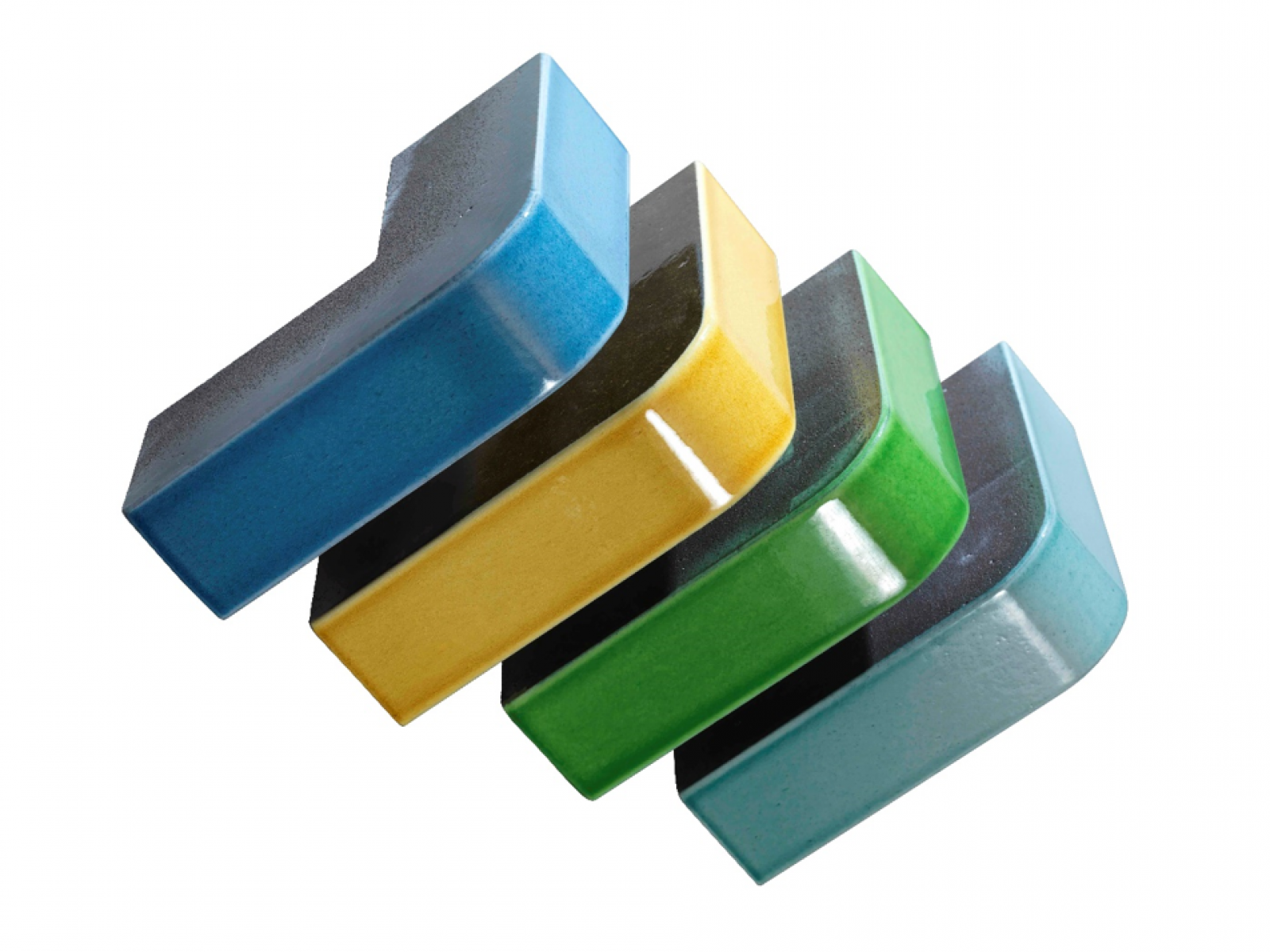

Edging is cut by CNC technology and finished by hand. During the firing cycle, the enamel liquifies and the surface tension changes the thickness of the glaze around the edges. The resultant lighter and darker variations at the edges on translucent colours is a signature characteristic of Pyrolave.

CLICK ON AN EDGE PROFILE TO ENLARGE & SPIN